Control for dry feeding

High-yield value creation – sophisticated technology

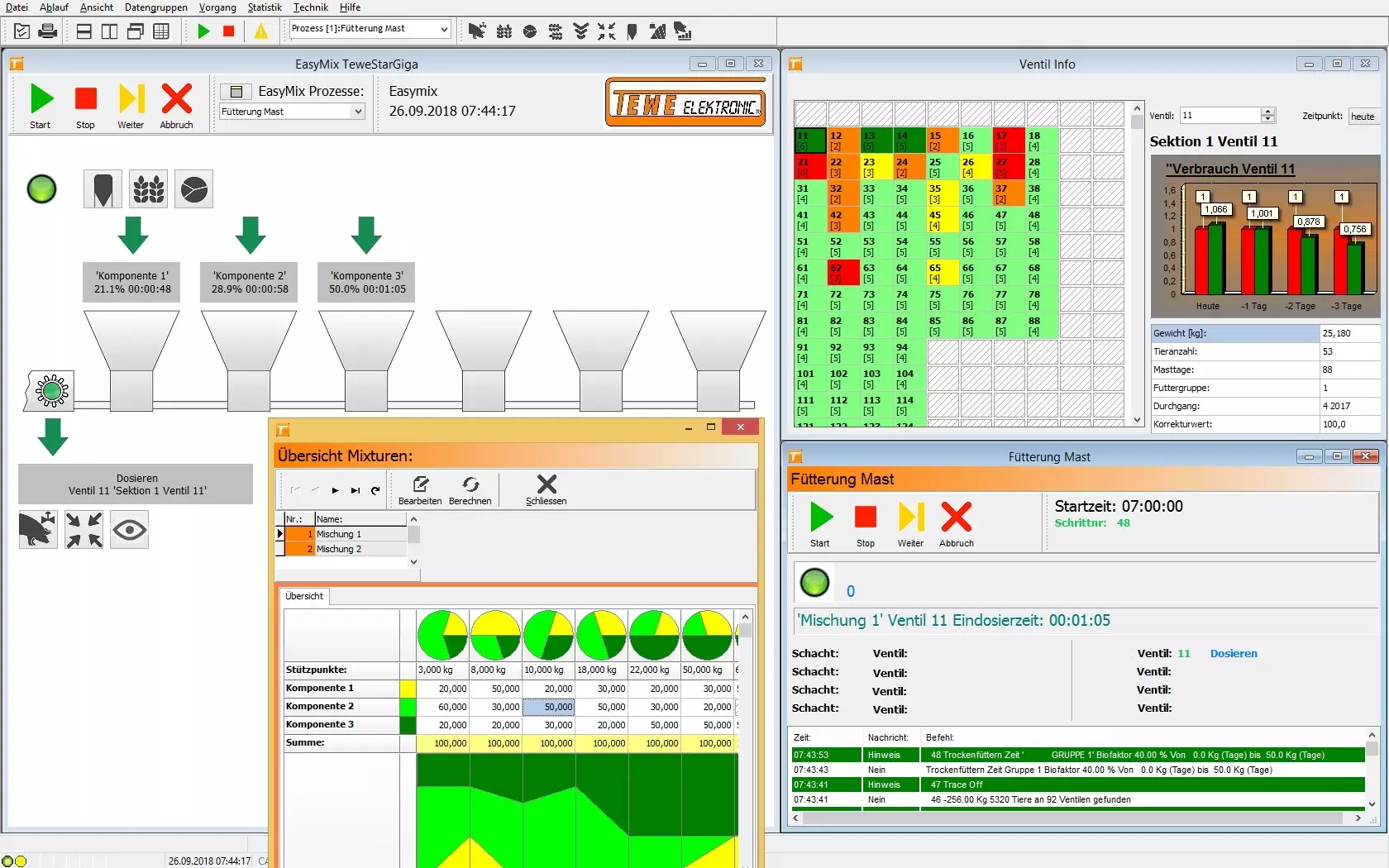

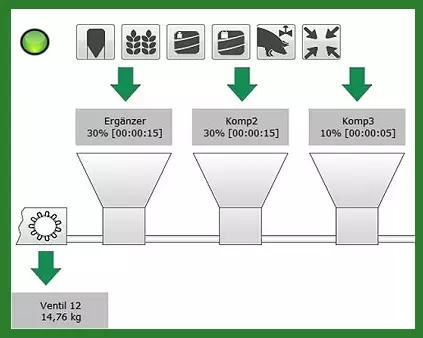

TEWE controls for dry feeding offer high-yield value creation and well-developed technology. This technology allows dry feed, meal or pellets to be efficiently delivered from the silo or feed kitchen to the animal. The high degree of automation and versatile setting options make these control solutions an indispensable component of modern farm management.

Users can access a wide range of functions and analyses which ensure high-yield value creation:

- ad libitum feeding (piglet, fattening pig)

- batch feeding

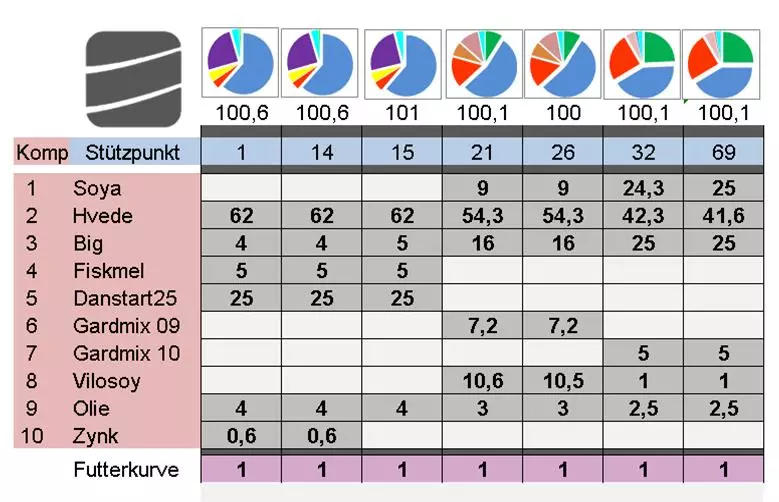

- multi-variety feeding

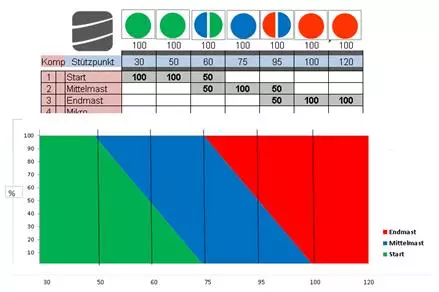

- phase feeding

- integration of additive dosing systems

- Batchfeed

- on-demand feeding

In conclusion

TEWE controls for dry feeding combine advanced technology with high flexibility and efficiency. They give farmers precise control over feed production and enable cost-effective, hygienic, needs-based feeding of the animals. With continuous development and individual adjustment, TEWE remains a pioneer in agricultural control technology which supports its customers with tailored solutions.

Benefits

- Energy efficiency:

The controls are designed to minimise energy consumption and thus reduce operating costs.

- Flexibility:

Dynamically adjustable replacement components and mixture counts allow feeding to be tailored to the needs of the animals.

- Precision:

Automatic calculation and overrun correction ensure precise mixing and dosing of feedstuffs.

- Hygiene:

The systems are designed to prevent contamination and ensure hygiene to support the health of the animals.

- Easy operation:

The user-friendly interface and automated processes ensure simple and efficient operation of the controls.

- Economical:

The optimisation of feed dispensing and the use of locally sourced ingredients ensure high value creation.

Features

- High capacity

The systems can handle up to 50 different components and several parallel processes at once.

- Individual adjustment

Customisable premixing times, overrun corrections and mixtures allow the specific needs of any system to be met.

- Automation

Automatic division of large mixing quantities, recording of all components in the target-performance comparison and programmable feed quantity corrections ensure seamless automation.

- Versatility

The controls are suitable for long conveying paths and can process various bulk materials without compromising hygiene.

- Low-maintenance

The systems are durable and low-maintenance, which further cuts operating costs and minimises downtimes.

References