TEWE controls

Well controlled – optimally fed

Since its conception, TEWE has been a specialist in the development and programming of electronic controls for livestock feeding. With over four decades of experience and practical innovations, TEWE is a global market leader in this industry. Thanks to continuous further development and customised adaptations, TEWE always stays one step ahead when it comes to technology.

All solutions offered by TEWE are controlled using our own control technology, which is available in combinable software modules:

- dry feeding

- liquid feeding

- piglet feeding

- Airfeed pneumatic feeding

- grinding and mixing

- fermentation

- CCM, crude fibre mixture

In conclusion

TEWE controls offer a comprehensive, flexible solution for modern agriculture. By combining state-of-the-art technology with user-friendly operation and the ability to adapt to customer demand, they are setting new standards in feeding technology. With TEWE controls, farmers can not only maximise the efficiency and precision of their feeding processes, but also optimise the health and wellbeing of their animals.

Benefits

- Parallel processes and requests: TEWE controls allow multiple feeding processes to be handled at once, increasing efficiency and precision.

- Clear evaluations and analyses: Thanks to extensive data analysis functions, farmers always have an overview of feed consumption, animal health and key operational figures.

- Individual process visualisations: The control systems offer user-defined visualisations which meet the specific needs of any system.

- LAN and WLAN connection: The controls can be seamlessly integrated into existing networks, enabling easy remote monitoring and control.

- Multilingual: The software supports multiple languages, making it easier for international users to operate.

- Easy step programming: Changes and adjustments can be made quickly and independently without disrupting the operational process.

- Custom feed curves: The ability to program custom feed curves allows feeding to be precisely controlled.

- Automatic data backup: All data is backed up at regular intervals throughout the operational process. The data is saved upon shutdown at the latest.

- Alarms and calendar functions: The controls feature integrated alarm and calendar functions for timely notification in the event of deviations or need for maintenance.

- Easy to expand: The systems can be easily expanded and adapted to new requirements through dynamic adjustment.

- Interfaces to PLC controls: The controls have interfaces for querying and triggering PLC controls, which enables seamless integration into existing systems.

Features

- High scalability:

The software modules are dynamically scalable and can be used in farms of any size.

- Limitless expansion options:

Modular architecture enables easy integration of special requirements and upgrades.

- Comprehensive data collection:

From the weight and target weight of the animals, to feed types, to energy, protein, vitamin and mineral needs – all relevant data is recorded and analysed.

- Automatic addition:

The software enables the automatic addition of any additives, such as minerals, vitamins or oils, which improves feed quality and animal health.

- Cost-benefit analysis:

With fiscal analyses and the option of managing several operating units, the software offers comprehensive economic analysis.

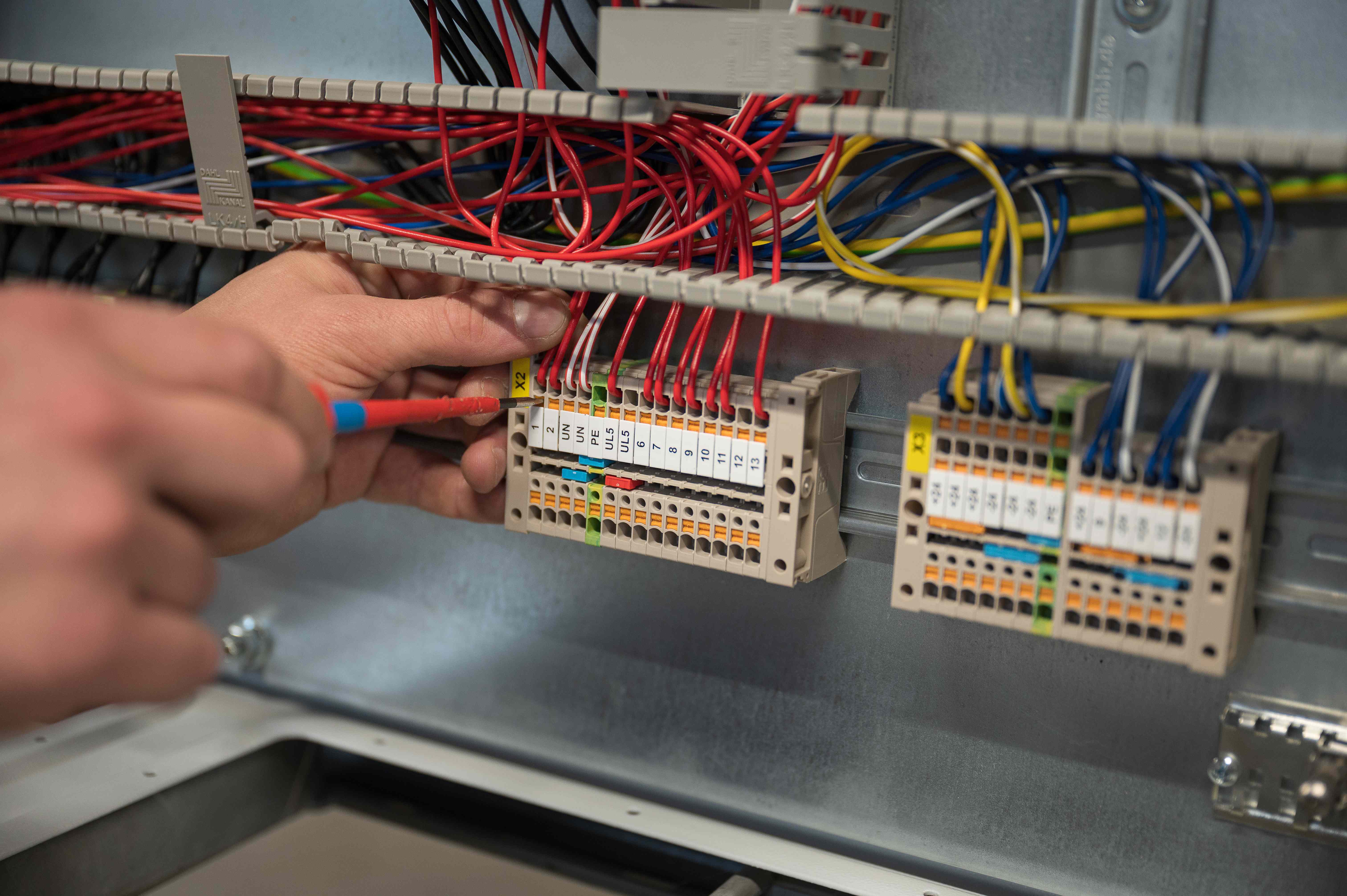

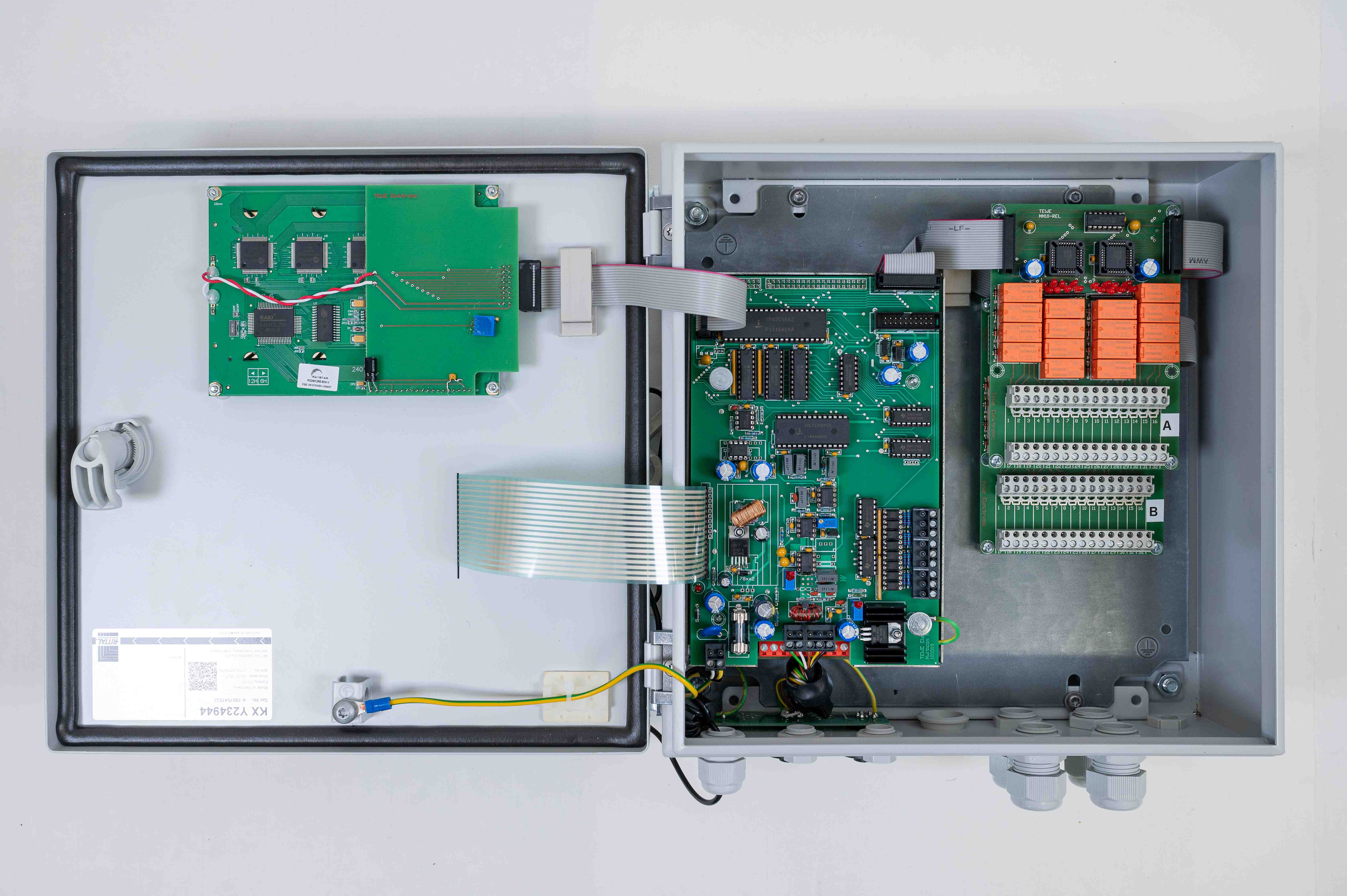

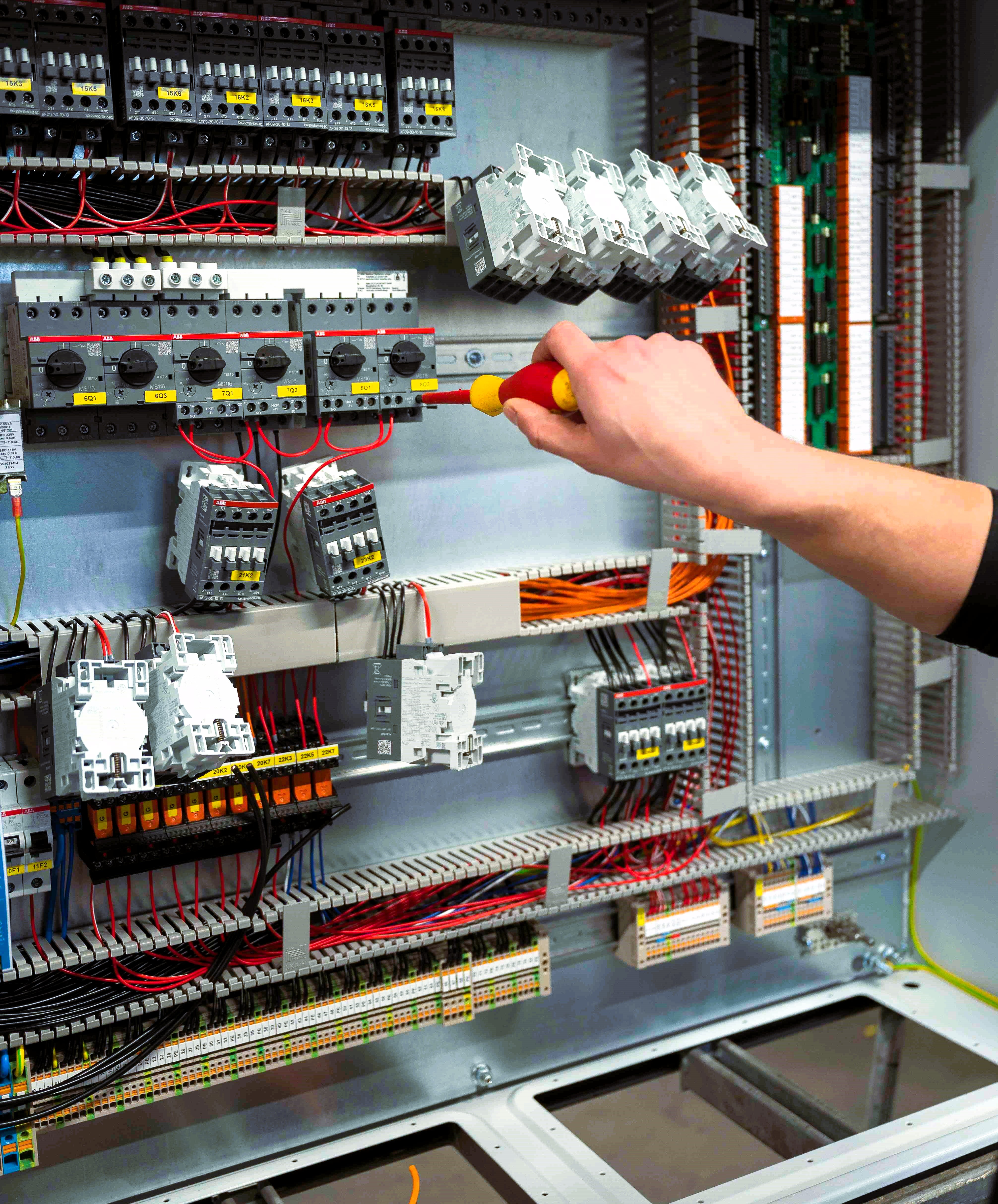

In-house production – made by TEWE

The software is designed for feeding pigs, cattle, calves, insects and fish, and can be easily expanded or adapted to suit the needs of the user.

TEWE's scope of supply and services includes the control of systems and processes, regardless of the supplier. If desired, TEWE takes charge of the whole supply chain from consultancy, planning and construction of the control system consisting of electronics and electrical components, to delivery of the control cabinet, installation, commissioning and maintenance.

Almost any customer-specific request can be easily integrated into the existing software modules. The company has its own trained staff for software programming in C, C++, C#, Java and PLC programming, as well as an electronics department for adapting electronic hardware and a technical design department for implementing the entire product range.

References