No-residue liquid feeding

All growing according to plan

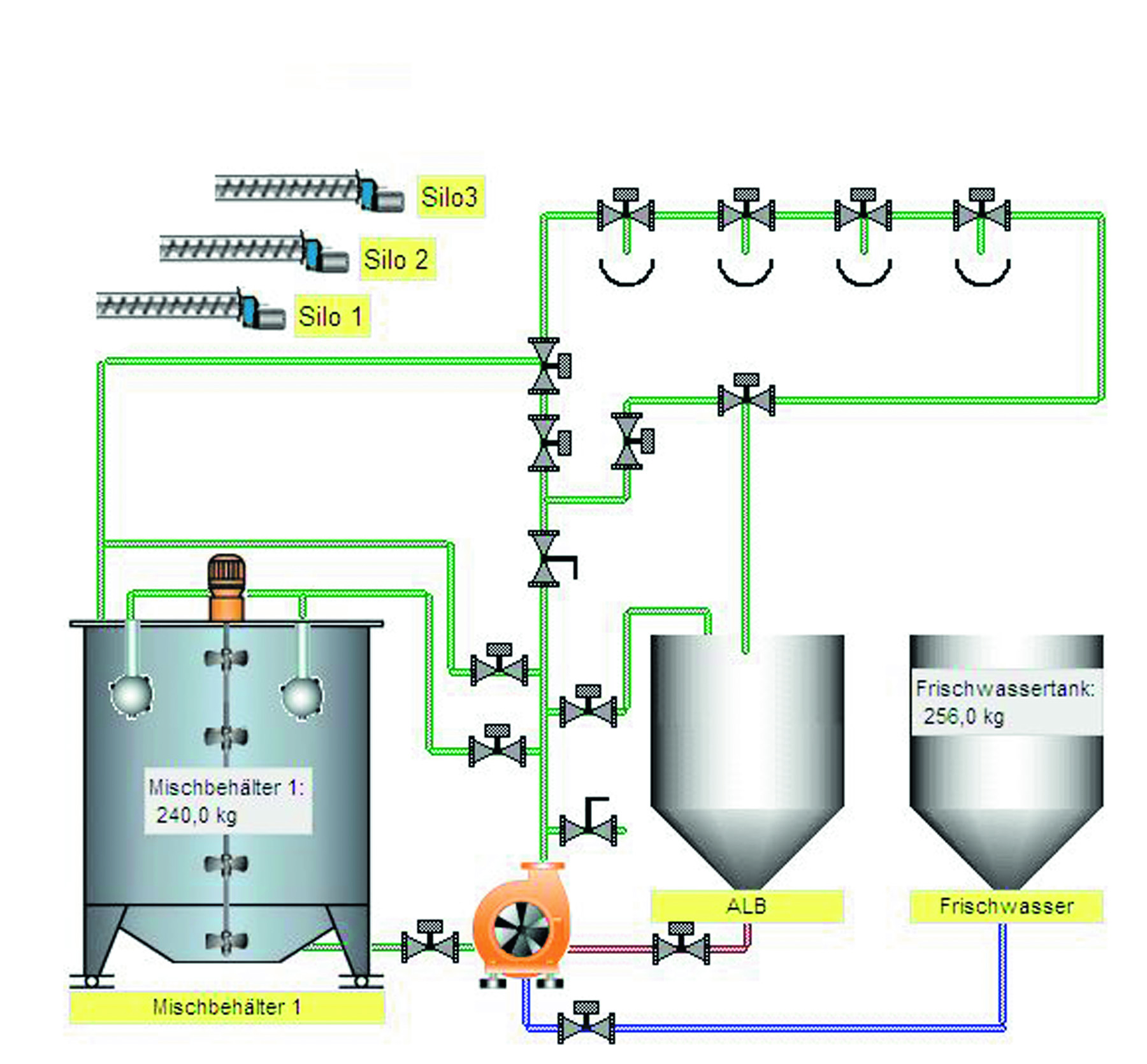

A functioning no-residue liquid feeding system guarantees optimal hygiene and well-fed, healthy animals developing in line with their planned weight gain. Not only does this require complete feed uptake, but there also can’t be any residues or waste left in the pipes or the feeding system. In order to ensure both of these things, a wealth of practical experience and no shortage of innovative technology have gone into the TEWE feeding computers and the development of the system for no-residue liquid feeding.

Our no-residue feeding optimises feed consumption while managing it to ensure that every animal always receives the nutrition it needs.

Another problem solved by the TEWE feeding experts was the potential for overfeeding, which would negate the positive effects of no-residue feeding. Because of this, the feeding computer collects all essential data, such as their age, weight, state of health and behaviour, to determine and monitor the exact amount of feed uptake required. This ensures that the animals don’t become obese or suffer other health damage – and that’s not to mention that it also prevents excessive feed costs.

In conclusion

A functioning no-residue liquid feeding system guarantees excellent hygiene, optimal nutrition and efficient feeding tailored to the needs of the animals. Precise control and complete feed uptake ensure the animals reach and maintain the ideal weight without being over- or underfed. This cuts feed costs and improves the health and performance of the animals. TEWE’s innovative technology ensures reliability and durability, even under demanding conditions, and contributes the success of farms.

Benefits

- Optimal hygiene and cleanliness: Liquid no-residue feeding ensures an outstanding level of hygiene, as no residues or waste are left in the pipes and the risk of contamination is minimised.

- Precise and efficient feeding: The automated control enables precise dosing and distribution of the feed, resulting in efficient, timely feeding.

- Optimal nutrition: Every animal receives the exact nutrients it needs to support its health and performance, with no risk of over- or underfeeding.

- Save time and workload: The automated control means less time and manpower are required for feeding, thus increasing efficiency.

- Flexible and adjustable: The feeding systems can be individually configured and adjusted to the specific requirements and conditions of any given farm, making them highly versatile.

- Proven reliability and durability: TEWE technology is tried and tested, and its durability means it ensures reliable performance over the long term, even under demanding ambient conditions.

Features

Complete feed uptake:

No-residue feeding ensures that animals get every nutrient from the feed. There is no residue or waste in the pipe which could be discarded or wasted.

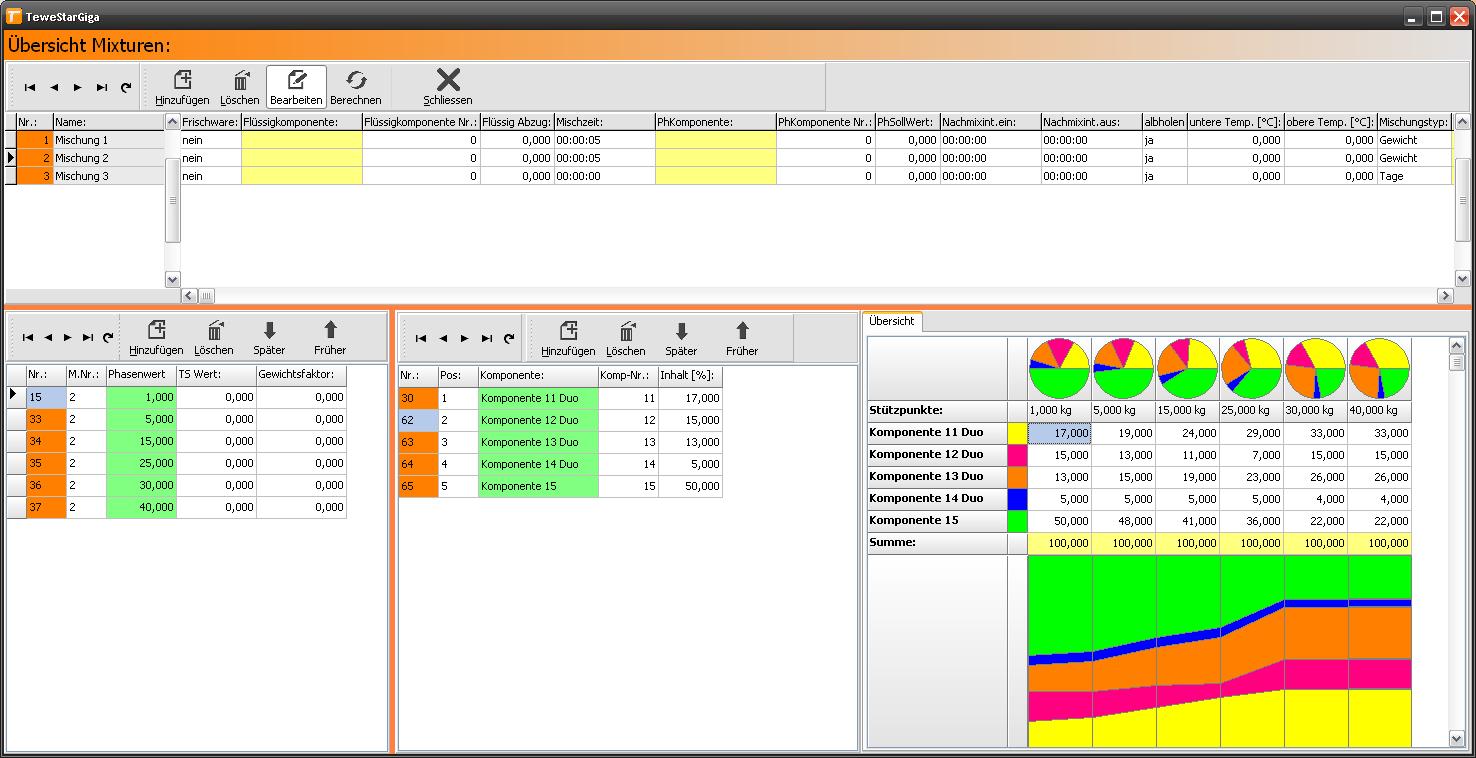

Proper mixing:

The tank and mixing technology paired with specially developed pumps, valves and control systems ensures homogeneous mixing of feed, nutrients, minerals and additives for batches of all sizes.

Monitored feed intake:

With no-residue feeding, the animal’s feed intake can be precisely monitored and controlled. This is particularly important if they need to be fed special diets or supplements to improve or maintain their health.

Hygiene and cleanliness:

Liquids spoil and become contaminated more quickly. No-residue feeding defines the exact batch quantity required for feeding. This prevents liquids sitting in the feed trough for too long, making bacterial contamination almost impossible.

Less waste:

With no-residue feeding, there is virtually no excess feed or water, meaning there are no leftovers that need to be disposed of. This cuts costs and results in more efficient use of resources.

TEWE’s no-residue liquid feeding optimises feeding processes, supports the animals’ health and makes farms more efficient, all of which contribute to successful and sustainable animal agriculture.

References