Industrial Automation at TEWE

End-to-end automation – architecturally designed, software-driven

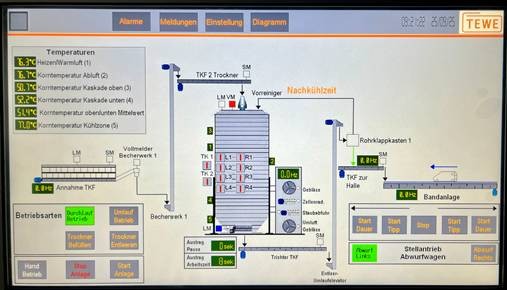

Industrial automation at TEWE does not start with the control cabinet, but with the architecture of the system. We develop automation solutions that not only connect processes, but logically integrate them – based on in-house software, clearly structured PLC architectures and an integrated SCADA layer, combined with deep process understanding.

The focus lies equally on the modernization and further development of existing plants and on the implementation of new, high-performance automation concepts.

TEWE Control Architecture

A Unified, Evolving Control System

From grown isolated solutions to a coherent control system

In many existing industrial and energy plants, control systems have evolved over time: different PLC generations, multiple manufacturers, proprietary modules and hardly compatible interfaces. Processes operate in parallel rather than as an integrated whole – extensions become complex, service effort increases and transparency is lost.

The addresses this challenge directly.

In-house development as the foundation

At the core of the Control Architecture is the consistent in-house development of control software. TEWE and TEWE-Biogas develop PLC logic, process sequences, SCADA systems, visualization and overall system architecture themselves – tailored to real operating conditions rather than rigid standard solutions.

The result is not a black box, but an open, transparent control and supervisory architecture that clearly represents processes, enables centralized monitoring and remains expandable over the long term.

Retrofit with a system approach – not piecemeal solutions

A key focus of the Control Architecture is the retrofit of existing plants. Instead of replacing individual control modules in isolation, existing systems are restructured at an architectural level: different control layers, sensors, actuators, peripherals as well as existing visualization and supervisory systems are consolidated into a unified PLC and SCADA architecture. This transforms a wide range of incompatible components into a cohesive, consistently operating system – stable, maintainable and future-proof.

Evolving instead of closed

The TEWE Control Architecture is deliberately not a closed system but designed as an evolving system. New processes, extensions or additional plant components can be integrated without destabilizing existing logic.

The SCADA layer is also modular in design and grows with operational requirements – both technically and economically.

Combined expertise from three domains

The strength of the Control Architecture lies in the integration of know-how from:

- industrial automation and material flow / feeding technology

- complex biological and technical continuous processes

- precise measurement and weighing technology from TELL

This expertise is embedded directly into PLC and SCADA programming – not as theory, but as proven, practice-oriented process logic.

Your benefits

- In-house software and SCADA development instead of standard integration

- End-to-end PLC and supervisory system architecture from a single source

- Retrofit expertise for heterogeneous legacy plants

- Open, expandable and maintainable over the long term

TEWE Control Architecture – when grown technology becomes a coherent system that continues to evolve.

In-house software development as the foundation

TEWE develops control software consistently in-house: from PLC logic and process sequences to SCADA systems, visualization and HMI concepts. This independence from proprietary standard solutions enables an open, transparent and long-term maintainable control and supervisory architecture.

Plants are not built around existing software, but are cleanly structured at both control and SCADA level, tailored to real operating requirements and future extensions.

Holistic automation – from analysis to operation

Industrial automation at TEWE covers the entire lifecycle of a plant:

- Analysis of existing processes and control landscapes

- Development of a unified PLC and SCADA architecture

- Programming, control cabinet manufacturing and commissioning

- Operation, monitoring, optimization and extension during runtime

The result is not a collection of individual components, but a coherent, logically structured system – from field level to supervisory level.

Retrofit of existing plants – a key focus

Many legacy plants have grown over years: different control modules, multiple vendors, hardly compatible interfaces as well as heterogeneous visualization and supervisory systems. Extensions become complex, service effort increases and transparency is lost.

TEWE addresses this challenge with a systematic retrofit approach. Existing sensors, actuators and peripherals are integrated and, together with existing supervisory systems, consolidated into a unified PLC and SCADA structure.

The objective is a consistently operating control and supervisory solution that restores stability, maintainability and future viability – without unnecessary mechanical intervention.

TEWE Control Architecture – the unifying system

The result of this approach is the TEWE Control Architecture: a unified, evolving control system with integrated PLC and SCADA architecture, developed from in-house software expertise and decades of experience in industrial automation, material flow and feeding technology.

The system is deliberately not closed, but designed for expansion – for plants that are intended to evolve.

Industries & applications

TEWE industrial automation is used wherever processes must be controlled precisely, reliably and transparently, with centralized monitoring – in particular in:

- industrial and conveying systems

- dosing, weighing and material flow systems

- automated feeding and mixing processes

The integration of precision weighing technology from TELL is a fixed component of many solutions.