Liquid feeding – you should know

Powerful and durable

TEWE has been developing and supplying liquid feeding systems for over 40 years, during which time it has gathered a considerable amount of knowledge in this area. Today, TEWE liquid feeding has been technically perfected and is among the world’s best systems, with a wide array of advantages.

The system exclusively features powerful, durable and long-lasting technology, as is reflected in the quality of the valves, pumps and sensors. Stringent hygiene standards are guaranteed throughout the entire process. At the heart of the system is the feeding computer with CAN bus technology, featuring a wide range of program and automation options.

The liquid feed can be mixed in automatically in the feed kitchen and then combined with other nutritional supplements such as proteins, vitamins and minerals. The feed can also be produced from ready-made feed mixtures.

The exact composition varies depending on the individual nutritional needs of each animal. Various mixtures can be programmed to account for different genetics, ages and weight classes. The prepared feed is then delivered to the animals through a pipe system using powerful pumps. Electropneumatic valves ensure that the right mixture reaches the right feed trough in the right amount.

TEWE offers various liquid feeding solutions with any desired capacity:

- Standard feeding (retention of residual feed and mixing of fresh feed)

- No-residue feeding (pipe rinsing with water)

- On-demand system with sensor technology

- Separator feeding (input of different feed mixtures and emptying/cleaning)

- Centralised feed production combined with decentralised blending and feed management for large animal populations

All solutions feature extensive hygiene measures and optional or integrated cleaning concepts. In addition, feed additives can be added centrally or decentrally via separate pipes without causing a delay.

In conclusion

TEWE liquid feeding solutions stand out for their performance, durability and flexibility. They provide a comprehensive, customisable solution which allows the different nutritional needs of animals to be met. The central control, combined with the ability to precisely dose various feed mixtures and additives, ensures optimal feed provision and a high standard of hygiene. This results in reduced food costs, minimises waste and promotes the animals’ health. TEWE’s innovative technologies and extensive know-how will make your farm more efficient and more successful.

Benefits

- Central feeding computer: Manages every process and feed curve for groups or individual animals.

- Adjustable feed mixtures: Meet nutritional needs based on adjustments for genetics, age and weight.

- Reduced feed costs: Efficient use of feedstuffs and minimised waste.

- High flexibility: Option to add silage and other byproducts.

- Homogeneous feed dispensing: A consistent supply of feed is guaranteed thanks to consistent mixing.

- Efficient pump systems: Transport various feed mixtures and running drinking trough programs.

- Significantly less workload: Automated quantity control reduces workload.

- Improved animal health: Less need for medicines and additives thanks to better health.

Features

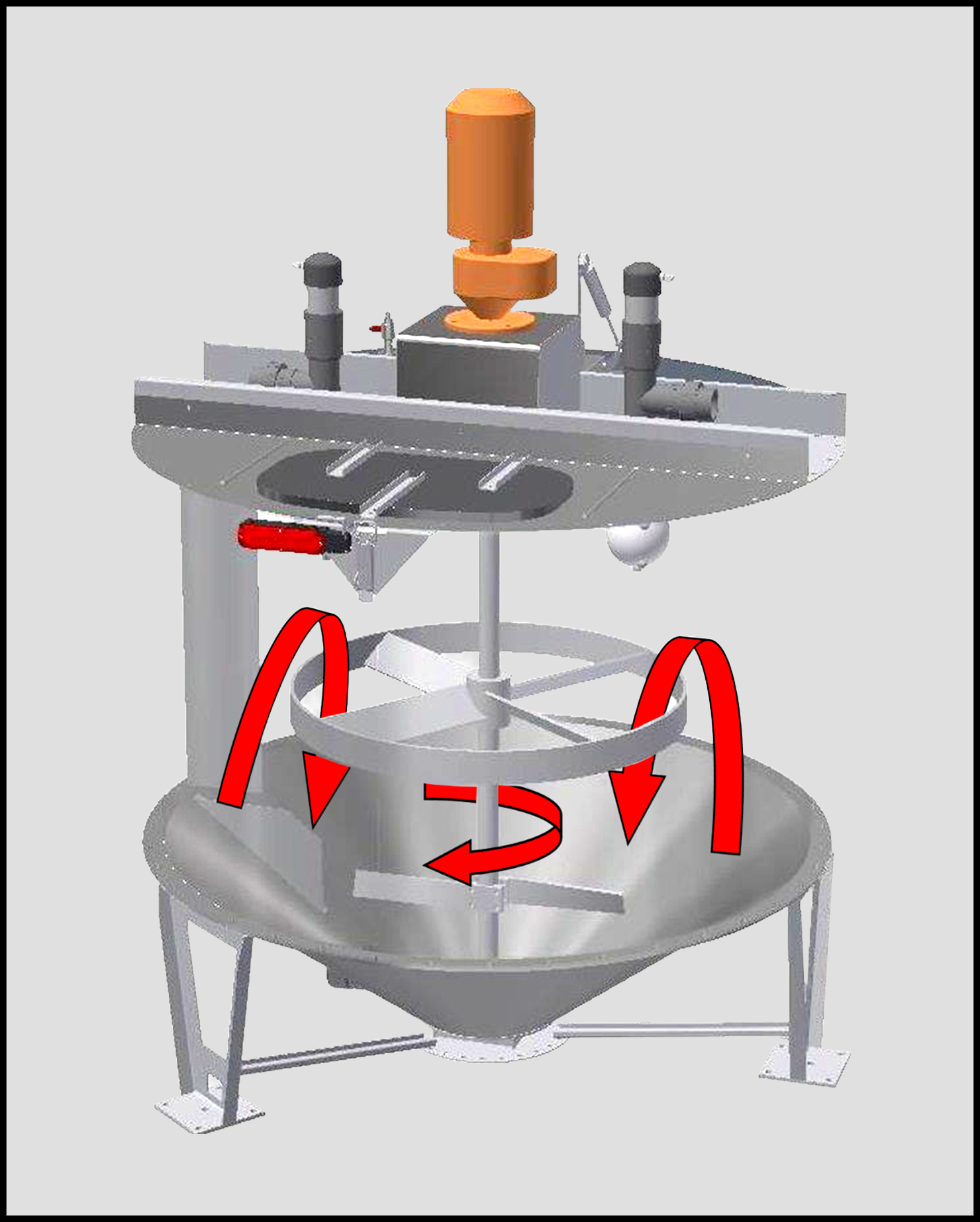

Various tank sizes and agitators: Suitable for small and large batches.

Easy pipe installation: Plastic tubes are used even for longer feeding paths and complex layouts.

Full automation: Automated systems maximise efficiency and flexibility.

Higher dose precision: Feed dispensed in exact amounts.

Centralised mixing and decentralised feed blending: Effective feed supply even to separate stables.

Easy to upgrade: Option to expand existing feeding stations.

TEWE liquid feeding systems ensure that animals receive an optimal supply of feed, while also reducing operating costs and increasing efficiency. This makes them an ideal solution for modern farms.

References