PLC & Electrical Engineering

Seamless, Transparent, Secure

Our Services

At TEWE, our focus in PLC and Electrical Engineering is on automating complex processes - reliable, energy-efficient, and future-proof.

We offer:

- Automated processes for bulk material and liquid transport

- Sensor technology for level, temperature, humidity, and CO₂ monitoring

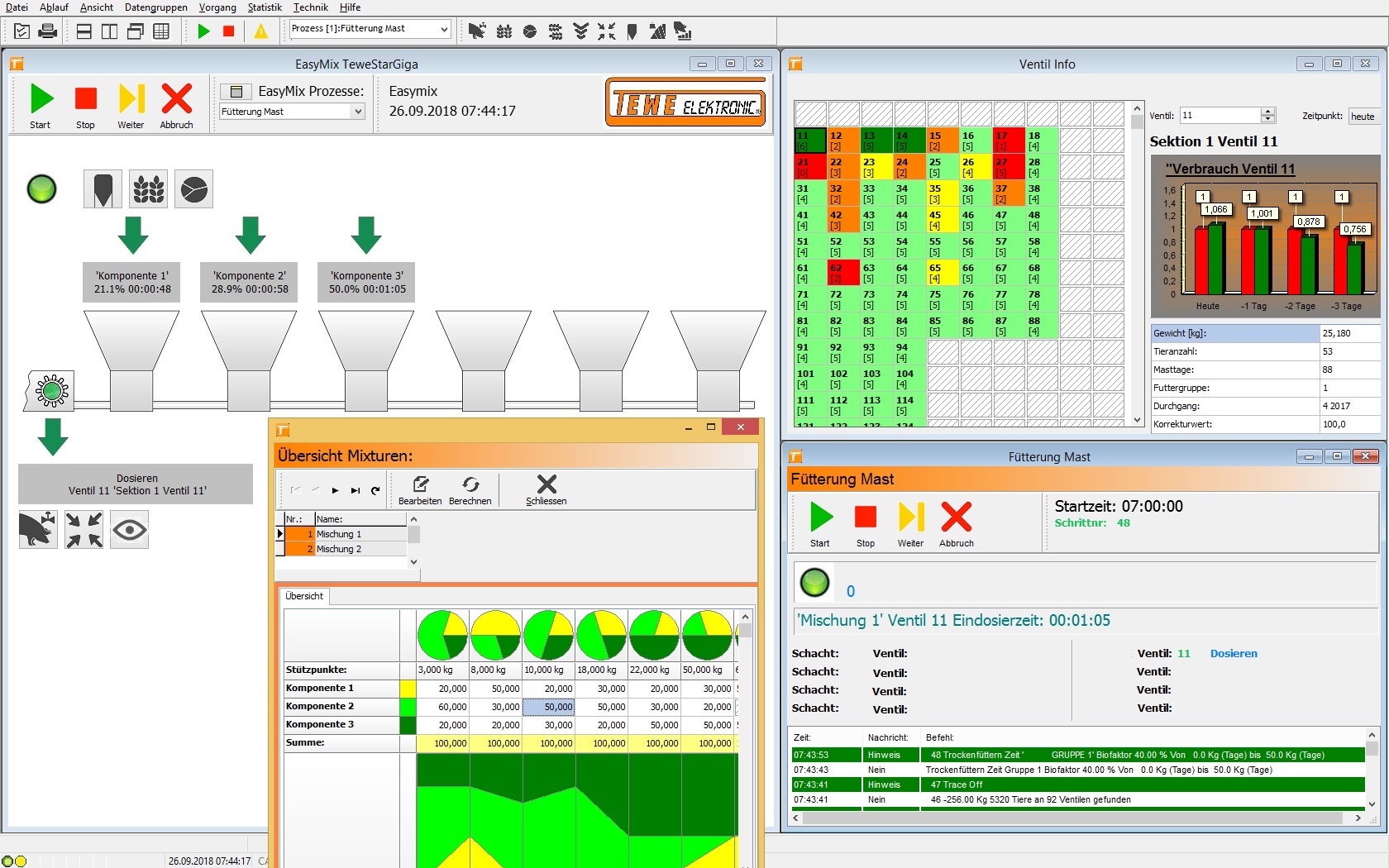

- Integration of sampling technology, grinding, mixing, and weighing electronics

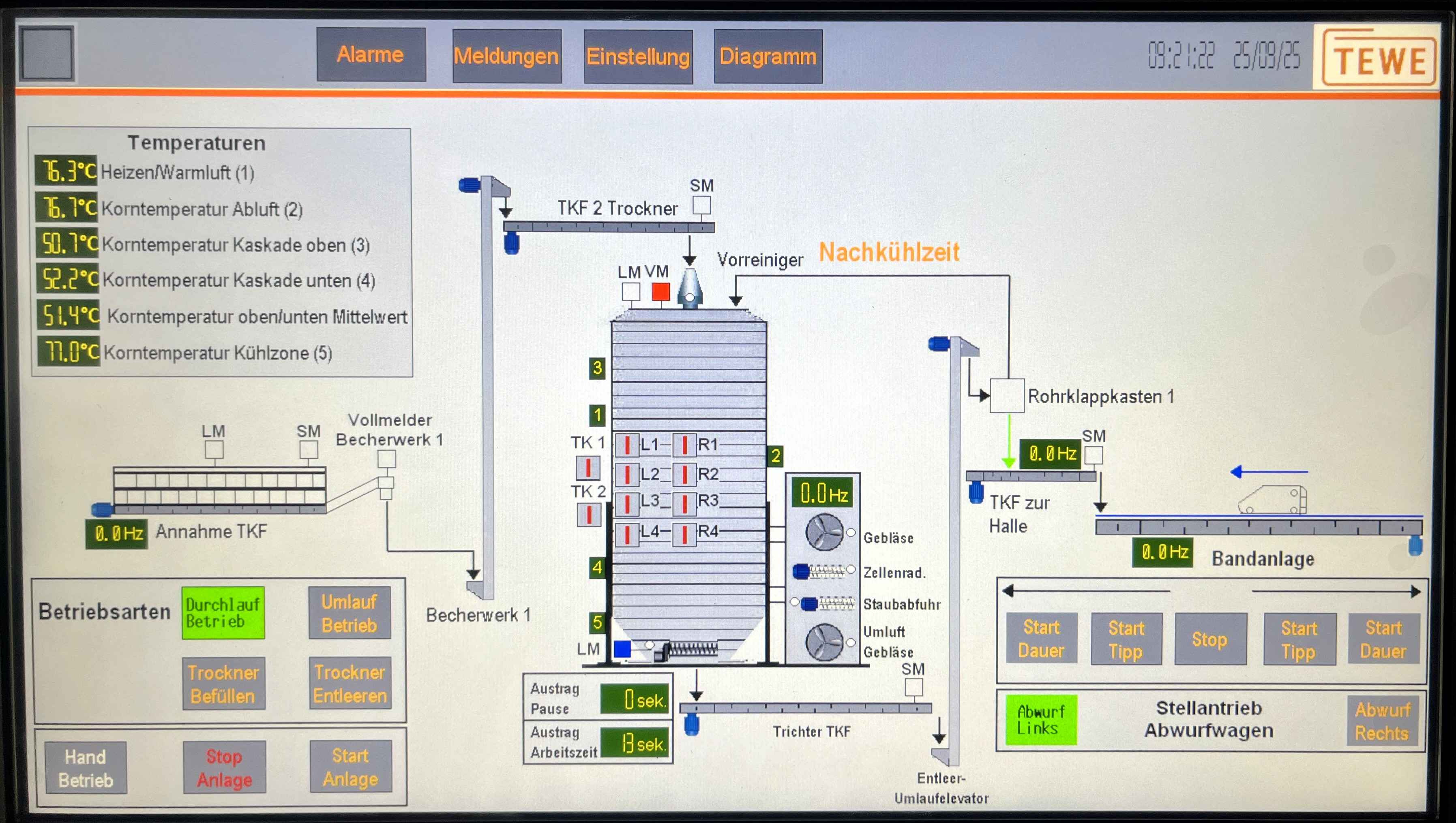

- SCADA process visualization

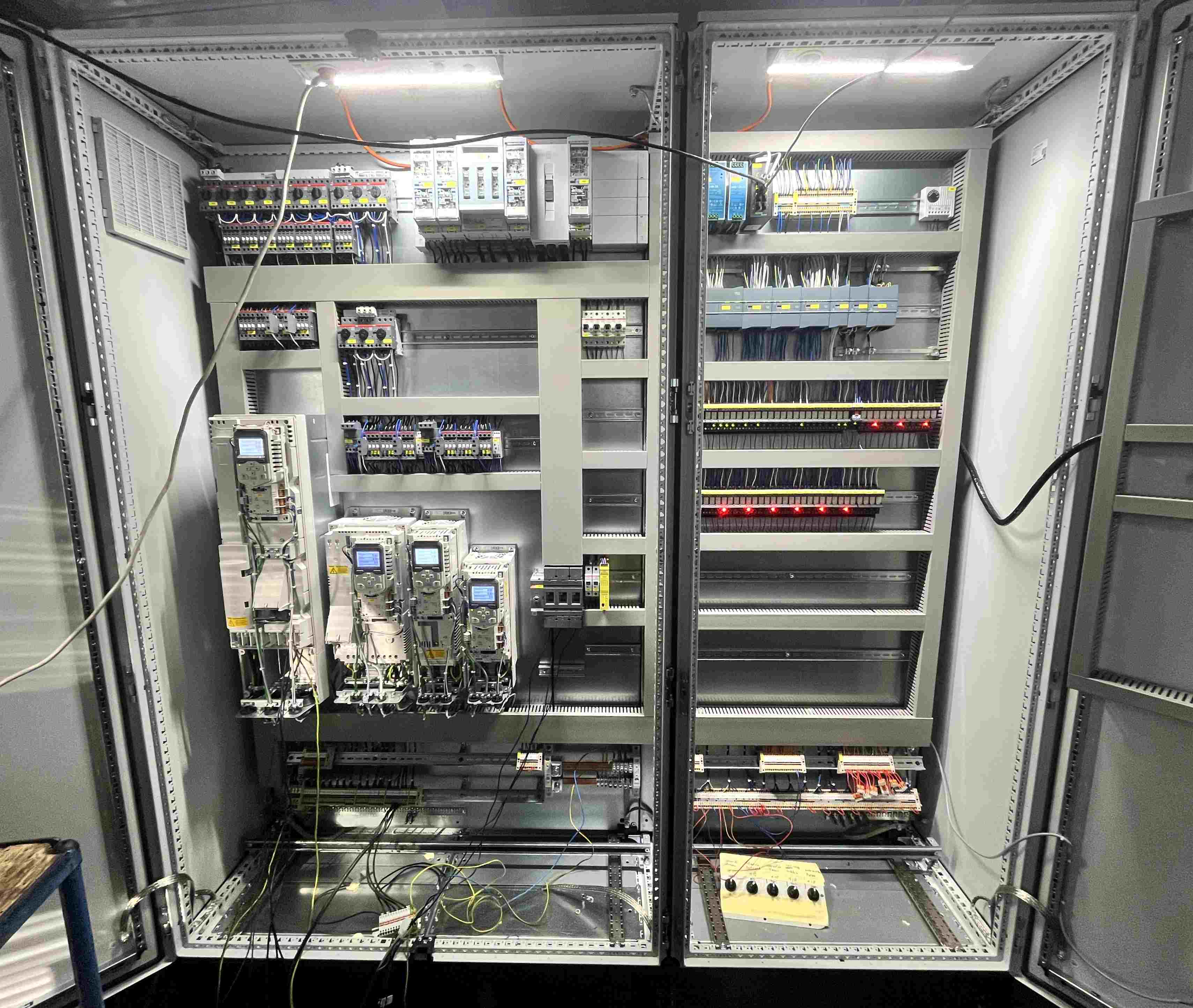

- Switch cabinet construction, installation, and service

- Solutions compliant with ATEX/EX directives

Application Examples

- PLC and electrical engineering, documentation, and monitoring of biogas plants or hygienization processes

- Automation of conveying and drying technology in silo facilities, flat storage, and port logistics

- Safety systems and quality assurance technology

TEWE utilizes logical functions in PLC programming to automate, document, and analyze specific tasks. Our IT department boasts extensive experience in integrating electronic and digital sensors and probes, such as light barriers, incremental encoders, limit switches, temperature sensors, and fill-level sensors.

Over the last four decades, TEWE has developed a comprehensive portfolio of program modules used across various application areas. These modules enable us to implement individual, cost-efficient, and rapid solutions for our customers.

In addition to software development, TEWE offers specialized solutions in C, C++, C#, and Java interfaces. Proven program modules are employed to meet specific requirements and ensure seamless integration into the overall control software.

Both decentralized and cloud-based storage solutions are available, depending on requirements, technical possibilities, and local conditions.

In conclusion

TEWE’s PLC controls reduce the programming workload and facilitate the integration of special solutions. The flexible and reliable control systems offer precise process control and enable seamless integration into existing infrastructures.

Your Benefits

All signals in one control system

- Retrofit & modernization – upgrading existing plants for future standards

- Extensions – integrating new technology into existing systems

- Switch cabinet construction & PLC programming – tailored to each facility

Centralized process control

- Silo and storage facilities: level, ventilation, emptying, filling

- Conveyors, bucket elevators, cleaners, inline scales, dosing systems

- Drying systems: energy-efficient and automatically regulated

Intelligent additional solutions

- Camera-based vehicle recognition

- Vehicle scales & weighing electronics

- Quality assurance with moisture, temperature, and CO₂ monitoring, sampling, traceability

- ATEX/EX and fire protection compliance

Greater efficiency & safety

- Energy savings through coordinated processes

- Reduced losses from mold, insects, or self-heating

- Complete documentation for audits & certifications

The result

Transparent processes, early fault detection, more efficient workflows. Your system remains reliable, expandable, and future-proof.

The TEWE Complete Package – Benefits for Decision-Makers

- All from a single source: PLC, electrical engineering, weighing and measurement electronics

- Flexible & adaptable: technology easily configured for individual requirements

- Future-proof: modular, cloud-ready, and always expandable

- Compliant: safety according to legal standards & insurance requirements

- Transparent & efficient: less energy consumption, fewer downtimes, lower personnel costs

Personal Consultation

Especially when it comes to complex plants, regulations, and safety requirements, personal consultation is essential. Many details are best clarified directly in conversation.

📞 Call us or send us a message – we look forward to hearing from you.

References