AIRFEED – you should know

The all-rounder – fast, individual, hygienic and precise

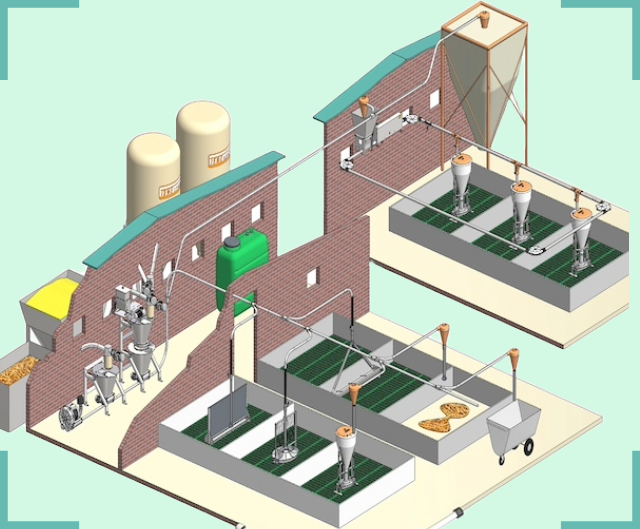

In pneumatic feeding, the feed is transported by air flow from the dosing and mixing station or storage container to the feed troughs.

This ultra-efficient system is offered by TEWE under the AIRFEED brand and is an efficient, hygienic and customisable solution for feeding livestock which greatly aids in improved animal performance and simplified feeding processes.

In line with the respective requirements, the AIRFEED system transports coarse or floury feed, straw, pellets, and thus all free-flowing materials, to individual animals or groups. Optionally, feed transported to the animal in dry form can be liquefied at the trough so that the benefits of liquid feeding can also be reaped. Multi-phase feeding can also be carried out without issue.

The feed is individually adjusted to the needs of each animal or group – depending on their species, age and weight – using the TEWE feeding computer. The TEWE mixing and dosing technology prepares portions of all sizes with no downtimes and automatically mixes in minute quantities of additives. Airfeed is controlled via the central feeding computer which brings together all functions and processes.

Benefits

Speed and efficiency: Immediate transportation of the feed without delays or waiting times due to valve switching times.

Save time and workload: Automatic control reduces the workload and saves time.

Hygiene: The stainless steel construction and unobstructed transportation routes ensure excellent hygiene.

Clear pipes: No feed residues are left in the pipes, ensuring optimal hygiene.

Individual adjustment: Possibility to individually adjust the feed for each animal or group according to the species, age and weight.

Consistent feed quality: Consistent feed quality in small or large portions.

Versatile: Can be easily integrated into a wide range of pens and adapted to different conditions.

Climate adaptability: Designed for use in environments with high temperatures and humidity.

Hygiene standards: Meets all hygiene standards by minimising contact between animals and feed.

Improved animal performance: Improved daily weight gain, reduced energy expenditure and strong tolerance of the feed.

Individual feeding control: Option for individual configuration and adjustment of feeding control.

What TEWE pneumatic control systems can do:

Meets all hygiene standards:

- minimises contact between animals and feed to reduce contamination

- dry feed transported from the mixer directly to the feeding station

- mash preparation takes place directly above the feeding station

- feed pipe free of feed residue thanks to unobstructed conveyor path from the rotary valve to the feeding station

- feed pipe above the mixing head with quick-release fastener for inspection

- highly effective rinsing programs developed in-house with fresh water directly above the mixing head

Good trough hygiene:

- small portions fed in

- trough kept clean at all times

Improved efficiency and animal performance:

- up to 20% more daily weight gain

- reduced energy expenditure

- decentralised control system prevents corrosion and increases service life

- no weight loss when changing feed

- high tolerance thanks to up to 30 daily feeding times

Individual feeding options:

- individually configurable with the TEWESTAR computer

- individual feeding stations with specific mixtures and energy densities possible

- multi-phase feeding with infinitely variable phase blending

- mixtures for each trough or valve group depending on the weight of the animal

- feeding may be adjusted to the individual requirements via sensors or according to the feed curve

References