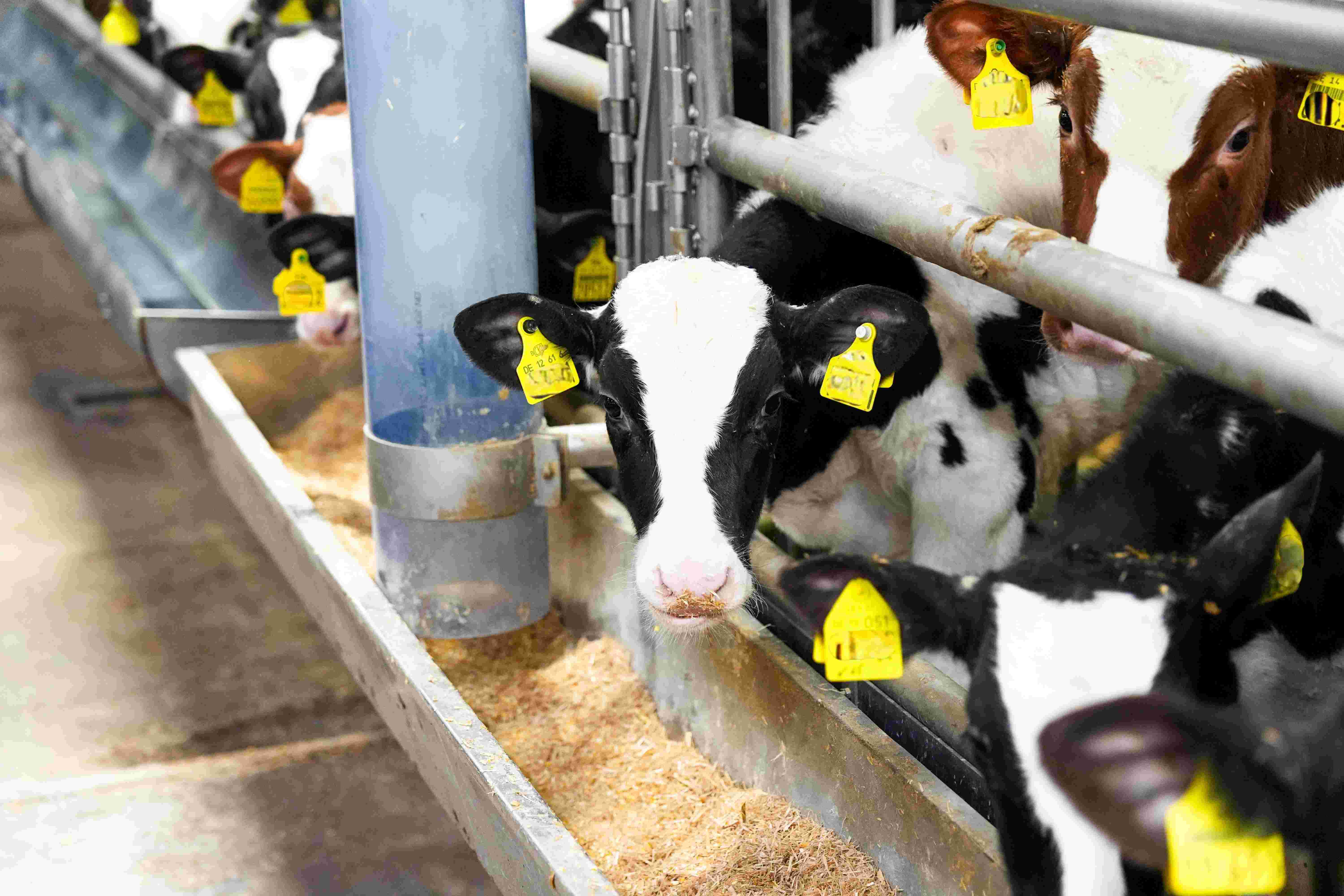

Calf Feeding with Roughage via AIRFEED

Improved Animal Welfare in the Barn

The TEWE AIRFEED solution for roughage supply to calves provides a fully automated, hygienic, and efficient roughage feeding system via air flow. With its innovative technology, it optimizes farmers' working time, ensures precise and individualized feeding, and can be flexibly integrated into existing feeding systems – all while maintaining the highest hygiene standards and high feeding performance.

Summary of Benefits:

- Individual Mixture per Trough: Each feeding station can receive a tailored mixture for the calves.

- Precise Feeding: Adjustment of feed quantity as needed (rationing or increasing).

- High Hygiene: By using stainless steel piping and thoughtful technology, high hygiene standards are maintained.

- No Maintenance Issues: No complex maintenance work, unlike chain or rope feeding systems.

- Expandable and Flexible: Easy-to-expand systems that integrate well into existing barns.

- Versatility: Suitable for various types of roughage and different barn layouts, including older barns or narrow buildings.

Conclusion:

The TEWE AIRFEED technology provides an innovative, reliable, and hygienic solution for calf feeding. It combines high feeding performance, automation, flexibility, and easy expandability to minimize labor while optimizing animal health and nutrition. This makes it the perfect solution for farmers who value efficiency and sustainable animal husbandry.

Features and Performance Description

- Roughage Supply via Airflow: Efficient transport of various roughage types like maize silage, straw, pellets, and cob grist via air.

- Fully Automated Control: Adjustment of feed rationing via the control computer. Automatic modification of feed rations and feeding times per animal and day.

- High Hygiene Standards: Thanks to the fully automated control system and hygienic piping (made of stainless steel), cleanliness in feeding is ensured.

- Optimization of Working Time: Automated feeding reduces manual labor and simplifies operations.

- Feeding with Various Roughage Types: Flexibility in feed choice, including maize silage, straw, pellets, cob grist, etc.

- Integration of Mixers or Buffer Silos: Easy integration with existing feeding systems.

- No Feed Segregation: Ensures even distribution of the feed mixture.

- Feeding via Pipelines: The feed is efficiently transported to the feeding stations via pipelines and auger dispensers.

Technical Details and Benefits

- High Feeding Performance: Up to 600 kg of dry feed per hour and up to 20 pipe switches in series for high capacity.

- Large Reach: Transports feed over distances of up to 200 meters, depending on the number of pipe switches in the line.

- Modular Design: Allows easy system expansion.

- Supply for up to 800 Calves per Airfeed Station.

- Easy Expansion: Can be flexibly adapted to growing needs.

- Hygienic and Low Maintenance: No disruptions like with chain or rope feeding systems (chain/rope breaks or defective pulleys). No leaky pulleys in the exterior and no clogged outlet pipes.

- Easy to Lay Pipes: Pipes can be easily laid through the barn floor, even in tight or winding barn layouts.

- Effortless Expansion: With its modular design, system expansion is possible without much effort.

- Automatic Feed Quantity Adjustment: The control computer automatically adjusts the feed quantities per animal.

Referenzen